Introduction

The objective of this project was to develop a paint for interior use for multipurpose zinc sheet ceilings. The research was aimed at achieving adequate thermal insulation, good anticondensation capacity and flame retardancy.

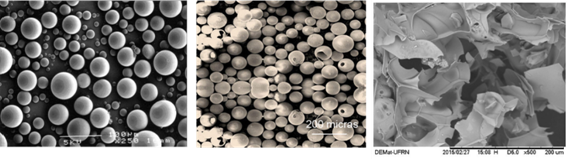

A fire-retardant latex paint was used as the formulation base and three types of fillers or complementary insulating fillers were evaluated: hollow glass microspheres, hollow ceramic microspheres (cenospheres) and expanded perlite, which are shown in Figure 1.These materials were selected for their ability to entrain air [1]. In a job with exterior latex paints, the use of up to 10% by weight of both hollow glass and ceramic microspheres is suggested [2]. The incorporation of hollow ceramic microspheres in an intumescent paint is reported to have achieved, after the flame exposure test, an increase in the residual weight of the protective film by 39.30%, which shows that it is a good component for intumescent paints. Furthermore, cenospheres increased the antioxidant capacity of intumescent carbon [3]. Regarding expanded perlite, its use as a thermal insulator has been widely spread due to its property of immobilizing the air present, avoiding thermal conduction by convection [4]. To determine the formulation with the best performance, the following were evaluated: the thermal transfer coefficient, the water retention capacity as an anti-condensation property, and the thermal transmission in contact with fire.

Figure 1: Hollow glass microspheres (HGM), hollow ceramic microspheres (HCM), and expanded perlite (EP), (as viewed from left to right).

Materials and methods

Thermal Transmission Coefficient

The determination of the thermal conductivity coefficient K (w/m.k) was carried out following the statements of Fourier's law for heat transmission by conduction, under the conditions of uniform and unidirectional heat flow; it was also considered that the thermal conduction coefficient is constant throughout the specimen.

A protected hot plate equipment was built under the ASTM C 177-04 standard, which includes two compartments to evaluate two samples at the same time. It consists of a central heating plate and two cold plates on each side. The heating plate consists of an electrical resistance supported inside an iron sheet metal casing, and then imprisoned by two 5-millimeter aluminum plates, consisting of an internal resistance of 200 x 200 mm of 500 W and an external one of 310 x 310 mm with internal depth of 206 x 206 mm also 500 W.The twocooling plates are made of 5-millimeter aluminum plates, to which coils of metallic copper pipes through which the water circulates were attached. The deviceis shown in Figures 2 and 3.

Figure 2: Front view of the equipment. On the left, the control of the two resistances that make up the central heating plate; on the right, the body of the equipment, where the specimens are mounted.

The mathematical expression used for this type of equipment is:

K = v.a/A[(DTi/Ei) + (DTd/Ed)] (1)

v: electrical voltage, measured in volts.

a: electrical intensity, measured in amperes.

A: transfer area, measured in square meters (m2).

DTi: temperature difference between the hot plate and the cold plate, in the left cabinet, in degrees centigrade.

DTd: temperature difference between the hot plate and the cold plate, in the right cabinet, in degrees centigrade.

Ei: thickness of the specimen housed in the left cabinet (m).

Ed: thickness of the specimen housed in the right cabinet (m).

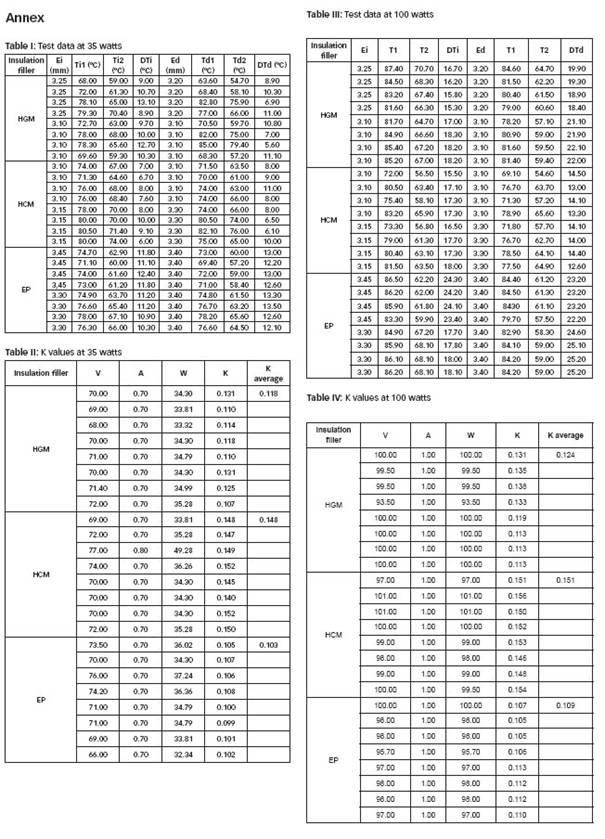

For the determination of the thermal transmission coefficients, four specimens of each formulation were prepared, two tests were implemented, and four temperature readings were taken at two different powers, 35 and 100 watts. This led to a total of 16 K values for each formula. These data were statistically analyzed to draw conclusions.

Flat galvanized sheet metal 0.4 mm thick and 0.30 m x 0.30 m on each side was used as a substrate, according to the measurements of the equipment cabinet where the samples were placed.

Successive cross layers were applied until a thickness of approximately 3 mm was achieved. For the measurement of the film thickness, a Demeq brand equipment, model QC3 F, of magnetic induction, was used for ferrous substrate.

Two CEM DT-3891G digital thermometers with a resolution of 0.1 ºC were used to measure temperatures, each with four type K thermocouples, insulated in fiberglass with a compensated connector suitable up to 700 ºC.

Four temperature probes were attached to each specimen, two on each side, placing one in the center and the other on the periphery, both on the hot plate side and on the cold plate side. In this way, it was verified that the temperature was uniform, and that there was no loss of heat tangentially.

Figure 3: The equipment was insulated with a polyurethane foam membrane, a polyethylene membrane and a 5 mm corrugated cardboard box.

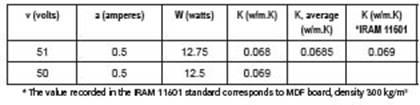

Test with medium density fiber board (MDF)

To have a reference, the value of the coefficient K of an MDF specimen was measured (Figure 4). The average value obtained was compared with the value registered in the IRAM 11601 Standard. The results are shown in Table 1.

Figure 4: MDF test specimen, with thermocouples, inside the equipment to measure K.

The average value obtained coincides with that of the IRAM 11601 standard. With this data, without being a certification of the measurements, it can be said that the equipment allows obtaining results within the order of expected values for this type of test.

Table 1: Values of applied power and K obtained.

Test with anticondensant-intumescent paint specimens

For the measurement of the K of the paint specimens, two power values were used in the heating resistance, 35 and 100 watts; equilibrium was reached by regulating the water flow rate and a range of 70 to 85 ºC was maintained on the hot plate.

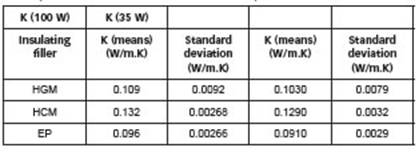

The K value was measured for the samples of the three antifogging-intumescent paint formulations. Two specimens were used in each trial; four specimens of each formula were made with an approximate thickness of 3 mm of paint. Four tests were carried out with each specimen at two power values, and 16 K values were then obtained for each.The values obtained in each determination are found in annex 7, tables I to IV. It was determined that the lowest value of K corresponded to EP, in second place, HGM and finally HCM.

Table 2: Mean values of K with their respective standard deviation values, measured with 100 and 35 watts of power.

Anti-condensation capacity

The anticondensation capacity of the different formulas was evaluated, making a parallel with the water absorption capacity in immersion and in the steam chamber. In this way, the interaction of paints with water in liquid phase and vapor phase was studied. The water absorption of each specimen was recorded until a constant weight was achieved or until defects appeared in the paint film, such as detachment, cracking or blistering.

Flat zinc sheet 0.4 mm thick, 0.30 m x 0.30 m on each side, was used as substrate. The three paints were applied until a dry paint thickness of 3 mm was achieved.

Water absorption test by immersion

For the immersion test, a tray with water was used as shown in Figure 5. Every 24 hours, the specimens were removed, superficially dried, weighed to record the weight of water absorbed, and re-introduced into the tray. The test was continued until the stability of the weight of the absorbed water was achieved, or until defects appeared in the specimens. The HCM and HGM specimens suffered blistering after 120 hours of immersion. The EP specimens remained without defects until water retention stabilized, which occurred after 10 days.

Figure 5: Specimens in the immersion tray, the size of the specimens is 0.3 m x 0.3 m.

One of the most useful parameters used in the formulation of a paint is the Volumetric Concentration of Pigments (PVC). Blistering of paints can be related to the critical pigment volumetric concentration (CPVC), which is the concentration for which all the voids between the pigment particles are filled with binder; that is, the demand for binder by the pigment is exactly satisfied. If the entry and exit of the water in the paint film is carried out in a stationary and controlled manner, blisters will not form. Also, the cohesion of the film, adhesion to the substrate, elasticity, washability, etc., must be ensured, according to the specific requirements of the selected protection scheme.

Blistering can be seen in two samples in Figure 6; they were characterized in accordance with the IRAM 1023 standard, resulting in the HCM samples “BLISTLED SIZE C, regular quantity”. In the case of HGM, the result was “BLISTRED SIZE D, little quantity”.

Figure 6: Left, painting with HCM. Right, painting with HGM. Both with blisters after 120 hours of immersion.

Water absorption test in steam chamber

Since liquid water is polar while water vapor is non-polar, a test was carried out in a closed chamber, saturated with steam, to see the response of the different formulations and compare data with the immersion test. In this way, the hydrophilic or hydrophobic character of the paints can be appreciated.

The specimens were subjected to saturated steam in the weathering chamber shown in Figure 7.

Figure 7: Front of the weathering cabinet.

The chamber was conditioned at 55 °C room temperature and saturated steam. The samples were exposed for 24 hours. At the end of the time, the absorbed water was estimated. The test was not extended any longer because after 24 hours the specimens were observed to be totally soaked in water, and the diffusion was no longer in the vapor phase. They were compared with the values of the two tests, the results are shown in Table 3.

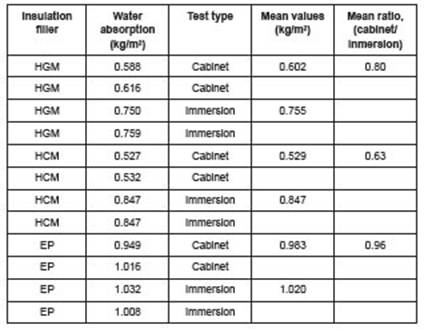

Table 3: Comparison of results of the two trials

The values obtained by the two methods were compared and related to know the behavior of the formulations. The ratio of kilos of water absorbed per square meter in the immersion chamber was 0.96 for EP, 0.8 in the case of HGM and 0.63 for HCM. From what was observed, the good affinity with water of expanded perlite stands out, both in liquid and vapor states, showing greater water absorption capacity than the other insulating fillers tested, and without generating defects in the coating film.

Flame thermal conductivity test

Reference intumescent paint

To compare the response to fire of the different paints prepared in this work, a pure intumescent paint was manufactured [5]. This was subjected to two performance tests; resistance to the intermittent flame of a Bunsen burner, which was carried out in the Pinturas Misioneras LLC laboratory, and resistance to fire due to the oven effect, which was carried out in the foundry workshop of the Provincial School of Technical Education Nº 1, UNESCO, from the city of Posadas, Misiones. This last rehearsal was in charge of Engineer Rubén Darío González, occupational safety and hygiene advisor, professional registration 0050 S. T. and E. Province of Misiones, Argentina.

Flame thermal conductivity test

The three antifogging-intumescent paint formulations were compared with the pure intumescent paint, using the flame thermal conductivity method. A cabin equipped with a Bunsen burner, a support for the sample and a temperature measurement system consisting of a CEM DT-3891G digital thermometer with a resolution of 0.1 ºC and a K-type thermocouple, insulated in fiberglass with compensated connector suitable up to 700 ºC (Figures 8 and 9).

Figure 8: Front of the Bunsen burner flame test cabin.

Figure 9: Arrangement of the specimen and the incident flame on the paint.

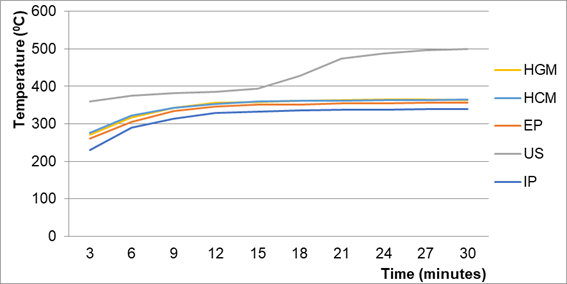

Next, the responses of the anti-condensation-intumescent paints were compared with each other, and with the pure intumescent paint.

The test seeks to reach 500 ºC in 30 minutes on the back of the fire in a bare sheet; for this, the height of the flame, the height of the test tube at the mouth of the burner and the gas dosage were varied. With the burner at 9 cm from the surface of the panel, the free flame reached 13 cm in height and 9 cm of blue cone, and the test tube was placed 9 cm from the mouth of the burner. Propane-butane gas was used as fuel gas. With these same conditions, three specimens were tested for each paint formula. Each test lasted 30 minutes, taking the temperature values every 3 minutes. The values obtained in each determination are found in annex 7, table V.

Results and discussion

Results of the thermal transmission coefficient tests

With the K values obtained, an analysis of variance was carried out to determine if the observed difference is relevant, and if there is an influence of the power value on the K value. The Statgraphics program was used. The lowest value of thermal transmission coefficient, and therefore the most favorable, was obtained with EP as thermal insulation load; paint with HGM came second, and paints with HCM came last.

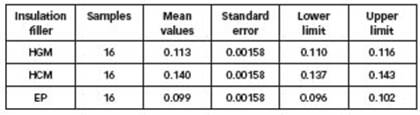

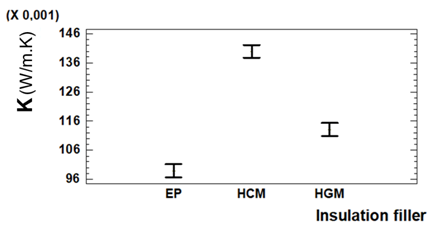

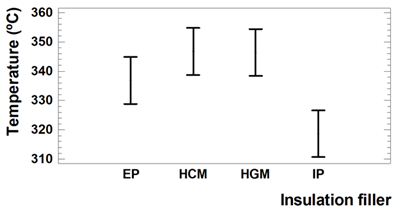

Table 4 shows the mean of K for each of the factors, in this case the thermal insulation loads. Also, it includes the standard errors of each mean, which are a measure of the variability in the sampling. The two columns on the far right show 95.0% confidence intervals for each of the means. The Figure 10 shows 95.0% confidence intervals for each of the means.

Table 4: Means by Least Squares for K with 95% confidence intervals.

Figure 10: Graph of mean values of K for the different insulating charges with their confidence intervals.

The thermal conductivity value of paints in general is 0.2 w/m.K [6]; In this work, with the use of PE, it was possible to reduce it to 0.099 w/m.K. The formula with HGM had a slightly higher value: 0.113 w/m.K and the formula with HCM gave the highest value: 0.140 w/m.K. It is concluded that the most appropriate filler to achieve thermal insulation in the paint formulation is expanded perlite.

Results of the water absorption capacity tests

It is important that an anti-condensation paint is akin to water, and especially in the vapor phase. In this way, the system acts efficiently absorbing, retaining, and desorbing water from the environment according to climatic requirements, avoiding dripping due to condensation. The best hydrophilic behavior was observed in the formula with EP, in second place, with HGM and in third place HCM. According to all the information that was collected during all the tests, it is considered that the determining factor to optimize the anticondensation capacity lies in the PVC/CPVC ratio. The excellent performance of the EP formula, which managed to remain immersed for 10 days without blistering or detachment, and which proved to be hydrophilic in the chamber test, shows that it has an optimal PVC value. This also implies that, both for the formulation of glass and ceramic microspheres, the optimum point can be found at a higher PVC value, which is an improvement factor for the use of these fillers.

Results of flame thermal conductivity tests

Knowing that with equal thicknesses, the pure intumescent paint would have an advantage over the anti-condensation-intumescent paints, differentiated thicknesses were used: 500 microns in the anti-condensation-intumescent paint test tubes and 300 microns with the pure intumescent paint. In this way, it was sought to obtain a relationship of equivalent thicknesses that give a reference for future applications.

A comparative graph was made (Figure 11), where the temperature values are expressed on the opposite side of the flame exposure, every three minutes. These values were compared with those obtained with the unpainted sheet (US). The three paints were evaluated with the different thermal insulating fillers, with each other and with the reference intumescent paint (IP).

Figure 11: Behavior of the specimens painted with the anticondensant-intumescent coatings, compared with the pure intumescent paint and the uncoated sheet metal.

The statistical program was used to perform the analysis of variance to determine if there is a significant difference between the paint samples. Pure intumescent paint with a dry film thickness of 300 microns was compared with antifog-intumescent paints with a dry film thickness of 500 microns.

The statistical analysis determined that there was no significant difference between the three thermal insulation fillers, but there was a significant difference between the pure intumescent paint and the three anticondensant-intumescent paints. This can be seen in Figure 12.

Figure 12: Means and confidence intervals of the temperature values for each anticondensant-intumescent paint, compared with the pure intumescent paint.

As expected, if part of the filler of the formulations, which is intended to strengthen the intumescence property, was used for thermal insulation filler under normal temperature conditions, the efficiency as a fire retardant would be reduced. Thus, in the working conditions of the test, a reduction of close to 30% of the temperature was achieved on the opposite face of incidence of the flame, with a thickness of 500 microns (behavior like that of fire-retardant paint with a thickness of 300 microns). From the results, it can be inferred that for a specific application of these paints as intumescent material, a thickness twice that specified for a pure intumescent paint should be used.

The test shows that, under extreme conditions of open flame, the three anticondensation-intumescent formulations do not provide a fire load as a conventional paint would and, in addition, provide a significant degree of protection against fire. Thus, it can be affirmed that the material meets the proposed objective.

Conclusions

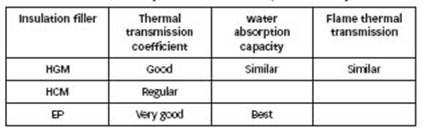

The influence on the paint properties of three fillers with conduction thermal insulation characteristics was studied, based on their ability to retain air within the dry paint film. Mainly, three properties were evaluated to define the best option: the thermal transmission coefficient, the water absorption capacity, and the flame thermal transmission. Table 5 outlines the results obtained:

Table 5: General summary of the results: comparative analysis

Selection of the best formulation

According to the results of the tests, it is concluded that the formula with expanded perlite is the most appropriate for anti-condensation, thermal insulation, and intumescent paint.

Paints with expanded perlite presented the best K value, which indicates that this composition provides greater thermal insulation by conduction. However, given that the ability to occlude air of the three loads studied (if related to the data on the density of the paints obtained) yields very similar values, it is concluded that the difference in behavior against heat conduction would lie in the alveolar structure of perlite, formed by curved plates that offer a more difficult and erratic path for heat to traverse.For their part, the hollow microspheres of glass and ceramic have a regular spherical structure, even though the spherical bodies touch at a single point, being densely compacted they form an ordered mesh, which favors thermal conduction.

Regarding the ability to retain water and release it without the formation of film defects, the expanded perlite presented excellent results. It showed similar affinity with water in the liquid state and in the form of vapor, and, in addition, it did not lead to film defects during the ten days that it required to reach the water saturation value by immersion.

Regarding the tests as fire retardant paints, the results were similar for the three loads. The work allowsconcluding that, if it wanted to use these paints with very high passive protection against fire, twice the thickness of that required for a specific high-performance intumescent paint should be applied.

Received: 13/05/2022

Accepted: 29/08/2022