Introduction

Pasta is a staple food, being the second most consumed in the world, due to its low cost, nutritional composition, versatility, ease of preparation, and sensory attributes (Monteiro et al., 2019). Normally, it is low in sodium and fat and provides a significant amount of carbohydrates and proteins, which is why it is considered healthy and should be included in a balanced diet (Foschia et al., 2015).

Durum wheat is the preferred raw material for making pasta (Maache-Rezzoug&Allaf, 2005; Sissons et al., 2005). Its gluten-forming proteins contribute to the development of the dough, avoiding disintegration or high loss of solids during cooking (Phongthai et al., 2017; Fiorda et al., 2013; Granito et al., 2003).

For some years now, the possibility of totally or partially replacing wheat with non-conventional flours has been studied, either to make pasta suitable for coeliacs, to improve its nutritional value, to take advantage of waste or abundant raw materials in certain regions or to reduce imports in countries or regions that do not produce wheat (Monteiro et al., 2019; Padalino et al., 2017; Foschia et al., 2015; Larrosa, 2014).

From a technological perspective, making quality pasta by substituting wheat for other flours always implies a challenge due to the gluten content reduction. The addition of hydrocolloids and proteins is commonly required to achieve the characteristics of a viscoelastic dough similar to the original (Romero et al., 2017).

Cassava (ManihotesculentaCrantz) is a possible substitute studied by various authors. Cassava or yucca is a native plant from tropical America, widely cultivated in all tropical areas of the world. The cultivation and harvesting of cassava can be done manually or mechanically. Its advantage over other crops is that it grows quite well on acid and not very fertile soil; in addition, it is very tolerant to drought (Aristizábal& Sánchez, 2007). Its roots constitute an important energy source and are used by the industry to manufacture starch, flour, and other secondary products. An innovation in industrialization would diversify production, consolidate the crop, add value, and favor the development of the agro-industrial chain. For all these reasons, increased cassava production could contribute to meeting the Sustainable Development Goals of the United Nations 2030 Agenda (NacionesUnidas, 2018). In Misiones, Argentina, the dehydrated cassava puree (DCP) stands out for its innovative character in several ways. DCP is obtained from cooking, mashing, drying, and grinding the roots, and could be used to make non-traditional pasta.

The properties of the DCP can be seen in the work of Cazzaniga et al. (2021).

The main difference between DCP and other cassava-derived products that are normally marketed to the public, such as flour or starch, is that in DCP the starch is pre-gelatinized due to its production process (Cazzaniga et al., 2021; Brousse et al., 2019). The pregelatinization of starch has various physicochemical and functional consequences over the product, inducing variations on doughs and finished products characteristics. Hence, the aim of this work was to evaluate the textural characteristics of pasta doughs substituted with DCP and gums in order to distinguish its effect and its similarities/differences concerning a traditional pasta dough.

Materials and Methods

2.1 Raw Material

The following raw materials were used to elaborate the dough: wheat flour (Molinos Río de La Plata S.A.), eggs (Roth S.R.L.), xanthan gum, locust bean gum, and turmeric, which were obtained from the local market. To carry out partial replacements of the flour, DCP was purchased in the local market of Misiones, Argentina.

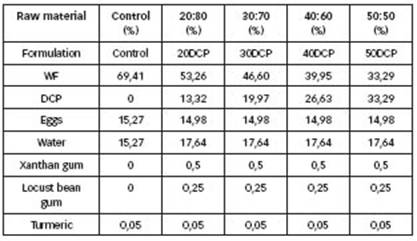

2.2 Preparation of the dough

Doughs were formulated with different proportions of DCP and wheat flour (WF) (DCP:WF): 20:80, 30:70, 40:60, and 50:50. An invariable amount of xanthan gum and locust bean gum were added to these formulations (Table I), to mimic the properties of gluten to form an elastic texture of pasta (Huang et al., 2001). An Atma pasta machine, model FP4070 (Newsan, Ushuaia, Tierra del Fuego, Argentina), was used to prepare the dough. During the manufacturing process, the solids were first mixed, then the previously reconstituted gums with a portion of the water from the recipe were added (Raina et al., 2005), and finally the liquid phase was incorporated. Since DCP has a higher water absorption (Cazzaniga et al., 2021), the amount of liquid phase in the doughs was modified. That is why in those formulations with DCP added, the amount of water was tested previously until a similar consistency to the control sample was obtained. The mixture was kneaded for five minutes and then left to rest for 30 minutes covered with plastic wrap to relieve the residual stresses acquired during its preparation (Limanond et al., 1999) and to avoid dehydration. Simultaneously, a control dough was prepared with WF, eggs, and water to obtain a reference textural behavior. The amounts of xanthan and locust bean gums and turmeric were kept constant in all formulations. Eggs and water portions remained constant between the formulations with the replacement of WF by DCP; however, these formulations required more liquid to counteract the greater water absorption of DCP concerning WF (Cazzaniga et al., 2021).

Table I: Percentage formulations of doughs tested.

2.3 Moisture

It was determined moisture on wet basis by the gravimetric method in triplicate assays. About 2 g of dough sample were placed in an air oven at 105ºC until constant weight.

2.4 Textural properties

The texture was studied with a TA.XT plus texturometer (Stable Micro Systems, Vienna Court, United Kingdom) equipped with a 50 kg load cell. All the texture tests were carried out 16 times for each formulation.

2.4.1 Texture Profile Analysis

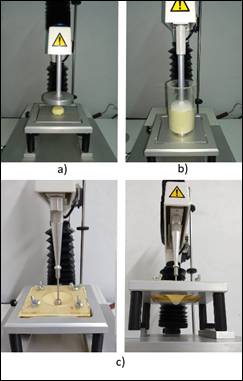

For Texture Profile Analysis (TPA), the dough was molded into cylinders within a plastic mold (30 mm diameter x 10 mm height). Then, it was taken out of the mold and allowed to rest. Each sample was placed on the equipment base and compressed twice to 20% of its initial height. A 75 mm disk was used for the test at a speed of 1.7 m/s (Figure 1-a). Force-time curves were obtained, through which four textural parameters were determined by using the software Exponent®: hardness (N), adhesiveness (g.s), cohesiveness, and elasticity.

Figure 1: Photographs of TPA (a), forward extrusion (b), and extensibility tests (c).

2.4.2 Extrusion analysis

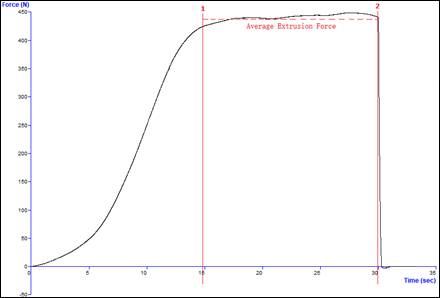

The consistency of the doughs was studied as the plateau force found by a compression-extrusion test (Figure 2), using the forward extrusion cell HDP/PE. For this, a constant volume of sample was used, avoiding the presence of air bubbles (Sciarini et al., 2010) and lubricating the container with solid petrolatum. Before the test, it was left to rest for 30 minutes covered with a film to avoid dehydration. A 49 mm diameter disk was used to compress the sample of 30 mm at a speed of 1 mm/s (Figure 1-b). The exit orifice had a diameter of 33 mm.

Figure 2: Representative experimental curve of forward extrusion test.

2.4.3 Biaxial extensibility analysis

To evaluate the extensibility of the formulations, the dough was stretched with a roller sheeter until it got a thickness of 2 mm. The dough was cut into sheets of 100 mm X 90 mm, which were later allowed to rest, covered for 30 minutes. The samples were placed on a platform designed for this purpose with supports at its four vertices (HDP / TPB) (Figure 1-c). A ½-inch spherical probe (P/0.5s) was used at a constant penetration speed of 1 mm/s. The extensibility (mm) was recorded as the distance at which the dough broke, and the toughness (N) was the maximum force exerted during the test.

2.5 Statistical analysis

The data were processed with the Statgraphics Centurion XVIII software. The statistical method of analysis of variance (ANOVA) was used, comparing the means with the test of least significant difference (LSD) at a significance level of 95%. The relationship between the parameters was determined by using Pearson's correlation coefficient.

Results and Discussion

3.1 Texture profile analysis

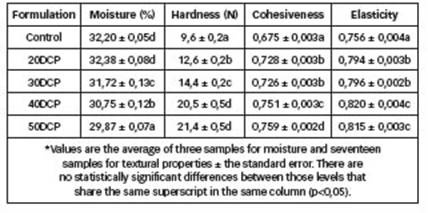

Table II shows the results of moisture on wet basis content and the analysis of the texture profile. Moisture decreased as the level of substitution increased, taking values lower than the maximum limit of 35% allowed by the Argentine Food Code and higher than the minimum limit of 24% indicated by the Italian legislation (DPR n. 187/2001).

Table II: Moisture and Texture Profile Properties.

The obtained data evidenced that the DCP increased the hardness of the doughs. In addition, the hardness has a negative correlation (p<0,05) of 0,89 with the moisture. Díaz and Hernández (2012) and Cazzaniga et al. (2021) found similar results with the increase in the level of quinoa flour and dehydrated cassava puree, respectively. Although the addition of hydrocolloids also causes greater water absorption (Linlaud et al., 2009; Rosell et al.,2001), Cazzaniga et al. (2021) found the same tendency in doughs prepared with dehydrated cassava puree, without gums. Given this evidence, the increased hardness in this work could be attributed to greater absorption of water, as a consequence of greater incorporation of starch and dilution of the gluten content. A similar result was obtained for bread doughs that contained potato flour (Xing-li et al., 2016). Cazzaniga et al. (2021) determined that the DCP solubility index and alkaline water retention maintain widely higher values than those of wheat flour. Both indices are related to the presence of damaged starch (Barrera, 2014). In this way, the greater hardness of the doughs formulated with DCP could be a consequence of the high hydration capacity of this ingredient, which reduces the amount of free water in the dough (Peng et al., 2017). Evenly, the hardness of the highest levels of substitution did not differ, even though a maximum could have been reached. However, more studies are needed to confirm this stand.

Cohesiveness is an attribute related to the forces that bind the components of a matrix (Rodríguez-Manrique et al., 2018). A significant increase in cohesiveness was observed when the DCP content increased, indicating a better unification of the dough ingredients. Elasticity showed similar behavior. Lindlau (2014) found that the addition of xanthan gum and locust bean gum to a wheat flour dough increases its elasticity, which could partly explain the increase of this factor in formulations with DCP compared with the control, which does not have hydrocolloids. Besides, Cazzaniga et al. (2021) reported the same elasticity and cohesiveness increasing trend in doughs substituted with DCP and without hydrocolloids. Thus, the physicochemical and functional properties of this product could also be responsible for this behavior.

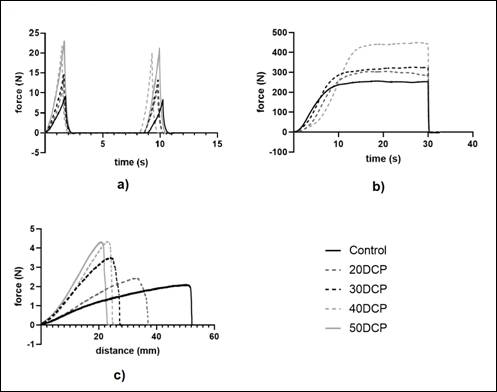

Doughs did not present adhesiveness. Figure 3-a shows the curves of the texture profile analysis for each formulation, in which the difference in hardness is appreciated, as well as the maximum value in the first peak of each curve and the absence of adhesiveness, like the non-existence of negative area.

Figure 3: Experimental curves of TPA (a), extrusion (b), and extensibility (c) tests.

3.2 Extrusion analysis

The test measured the necessary compressive force to extrude the dough through the exit hole. The force-time curve allowed evaluation of the maximum compression force, represented by the point where the slope changes and a plateau occurs. Such plateau is the force required to continue with the extrusion process (Ronda et al., 2013) and it was taken as an indicator of the dough consistency (Sciarini et al., 2010).

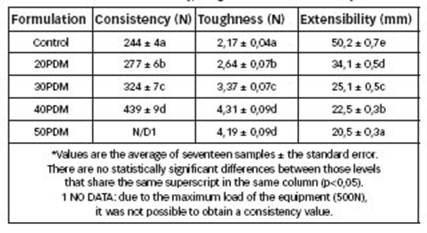

The consistency increased significantly according to the amount of DCP in the formulations (Table II); Figure 3-b shows this difference in the plateau of each curve. The formulation with the highest level of substitution (50:50) exceeded the maximum force of the equipment load cell (50 kgf ≈ 490 N), thereby it was not possible to obtain a value of consistency.

Ronda et al. (2013) found that the consistency of the bread doughs strongly depends on the amount of water contained in them. Moreover, Sciarini et al. (2010) observed that their gluten-free doughs with added xanthan gum have a notably higher consistency than the control (without gums). In this way, the results obtained in the present work could be associated; firstly, with the inclusion of xanthan gum in the formulations; secondly, with the moisture of the dough, which presented a high negative correlation (0,85); and lastly, with the DCP, which has a positive correlation with consistency (0,85), possibly due to the strong absorption and water retention capacity of DCP concerning the wheat flour (Cazzaniga et al., 2021), which leaves the matrix less hydrated and with a less plastic texture.

3.3 Extensibility analysis

The toughness (N) of the dough, which refers to the resistance to be stretched, increased with DCP content, while the extensibility (mm) decreased (Table III). Figure 3-c shows the force-distance curves, where the maximum value (N) of the peaks represents the toughness of each formulation and the horizontal distance to each peak represents the dough extensibility, at which point the dough breaks and the exerted force falls abruptly.

Table III: Results of consistency, toughness and extensibility.

Zhang et al. (2020) found that doughs with added soy protein provide greater resistance to elongation and are less extensible than a dough made from wheat flour. The authors attributed this behavior to the lower gluten content in the formulation and a disruption in the formation of its network. Besides, Carini et al. (2012) found that dough extensibility and toughness decrease with the replacement of wheat flour by whole carrot and soy flour, attributing this behavior to inadequate hydration of the gluten, which causes a weaker matrix. The behavior of the doughs studied in this work can be attributed both to the decrease in gluten content as the level of substitution increases, as well as to the higher water absorption and retention rate of the DCP compared to wheat flour, which produces a lower availability of water for the hydration of gluten, disrupting of the viscoelastic network. The high negative correlation between moisture and toughness (0,85) and the positive correlation between moisture and extensibility (0,70) support this hypothesis.

Correct handling at the industrial level in pasta production requires that the doughs have good resistance to elongation to avoid the rupture and present some extensibility (Larrosa, 2014). If the control dough is taken as a reference, the formulation with the greatest similarity in terms of the properties studied is 20DCP.

Although the dough is destined to processes that involve extrusion, the extruder must be able to impart more force in those formulations with a greater amount of DCP. The values found do not represent major inconveniences for industrial machinery since, in preliminary tests, the doughs have been extruded with domestic equipment, such as the one mentioned in the materials and methods section.

All the texture parameters obtained a positive correlation greater than 0,83 with the DCP variable, except for the extensibility parameter, which was -0,96. This means that the increase in DCP content can explain 83% or more of the variation in the texture of the doughs.

Conclusions

The results show that the replacement of wheat flour by DCP in pasta doughs generates changes in its texture. DCP causes the moisture of the dough to decrease, making it harder, more elastic, and more cohesive. In addition, the doughs with DCP turned out to be more consistent in an extrusion operation and more resistant to elongation during sheeting. Such doughs were less extensible than those with a higher proportion of wheat flour. It is concluded that the low moisture presented by the doughs substituted with DCP is responsible, at least in part, for the textural changes that they present. However, despite the observed textural differences, these formulations turned out to be appropriate for handling in industry, without forcing machinery or adhering to equipment. To establish an optimal formulation, future tests will be necessary to evaluate characteristics related to the quality and organoleptic acceptance of the pasta made from these doughs.

List of abbreviations

DCP: dehydrated cassava puree

WF: wheat flour

Acknowledgments

The authors would like to thank the Consejo Nacional de InvestigacionesCientíficasy Tecnológicas (CONICET) for the doctoral scholarship awarded to Ana B. Monaca. Also, the Facultad de Ciencias Exactas, Químicas y Naturales (FCEQyN) of the Universidad Nacional de Misiones (UNaM), Argentina, for providing the working place and equipment.

Disclaimers

All authors have contributed significantly to the paper and agree to its publication. They declare that there are no conflicts of interest in this study.

Received: 02/08/2022

Accepted: 09/03/2023