INTRODUCTION

The demand for high esthetic standards has made dental ceramic one of the most frequently selected materials due to its ability to emulate teeth. Dental veneers are conservative ceramic restorations often used to change the position, shape or even color of front teeth 1 . There is a wide variety of dental ceramics for indirect restorations that can be used for making veneers, including sintered or machined feldspathic ceramics, injected or machined glass-ceramics, resin-matrix ceramics such as resin nanoceramics (Lava™ Ultimate) and glass-ceramics in an interpenetrating resin matrix (VITA ENAMIC®) 2,3 . Feldspathic ceramic consists of potassium and feldspar. Its crystalline proportion is less than 20% in weight and average crystal size is 4 um. Feldspathic ceramics have high vitreous phase content and lower crystalline phase content, enabling better transmission of light. The crystals cause light scattering and diffraction. Glass-ceramics have a high degree of translucency, especially in thin layers. Ceramic thickness, color, composition and translucency can all influence light transmission and thereby, the degree of conversion of resin cements 4 .

The success of clinical treatment depends on the perfect combination ofcolors between the restoration and the tooth. Many variables are involved, such as the color of the tooth structure; the thickness, color, translucency and type of ceramic, and the properly polymerized resin-based luting agent. In addition, biocompatibility and integration of the luting agent with tooth tissues increase restoration longevity, reduce marginal microfiltration, and improve mechanical properties 5,6 .

There are light-cure and dual-cure resin-based luting agents, which may be used according to the opacity and thickness of the ceramic restoration. Light-cure resins are indicated for restorations with high translucency that allow light transmission, such as dental veneers. Dual-cure resins are indicated when a thicker layer of ceramic is used (1.5 to 2.0 mm), and its opacity interferes with light transmission. Nevertheless, many dental professionals recommend using dual-cure resin-based luting agents to attach veneers. The luting technique is also important for the clinical success of a dental veneer because optimum polymerization is required to achieve adequate bond strength 5 . Exposure time to light, and light transmitted through the ceramic affect the amount of light energy delivered to the resin-based cement 7 . During photoactivation, light must pass through the ceramic layer, which may be 0.3 mm to 1.0 mm thick, and through the layer of cement itself so that it will be appropriately polymerized throughout. Incomplete or inadequate polymerization is related to poor mechanical properties. Dental ceramic has been reported to attenuate photoactivation light. The degree of attenuation depends on several characteristics, such as ceramic crystalline structure, thickness and color 8-11 . The ceramic may absorb 20 % to 50 % of the spectrum corresponding to blue wavelength, affecting irradiance level for optimum polymerization7,8,12. Pacheco et al. analyzed the transmission of light of different wavelengths through indirect restoration materials. Photoinitiators may be sensitive to blue or violet light, depending on the type. Blue and violet light are transmitted differently through ceramic, determining whether sufficient light is available to photoactivate the material at the bottom of the resin cement 4 . Exposure time to the curing unit and the light transmitted through the ceramic are important for appropriate polymerization when luting a ceramic veneer. In light-cured resin-based materials, the reduction in energy density of light radiation may diminish the degree of conversion and the mechanical and physical properties, affecting marginal microleakage, and reducing color stability and bond strength 9 . In dual-cured resin-based cements, it has been shown that achieving a high degree of conversion and good mechanical properties depends on photoactivation. Kilinc et al. compared both types of resin-based cements, and found that in dual-cure resin cements, chemical curing alone was insufficient to achieve maximum conversion of monomers 13 . Jang et al. reported that light-polymerization and self-polymerization systems did not act synergistically. In dual-polymerization materials, photoactivation induces rapid polymerization, and the mobility of free radicals in the chemical curing system is limited by the growing network of cross-linking polymer chains, becoming trapped in an organic matrix during the initial phase of polymerization if there is not enough energy to complete the polymerization reaction. The same study analyzed self-cure and dual-cure materials with insufficient light exposure consisting of less than 20% of total polymerization time 14 .

Resin-based luting agent polymerization can be evaluated by testing microhardness, according to several authors6,15,16. Microhardness is one of the most important properties of dental materials. It is defined as resistance to permanent indentation or penetration of the material surface, and can be used to estimate degree of conversion. A higher degree of conversion is expected at higher microhardness values. Degree of conversion can be measured using Fourier-transform infrared spectroscopy, and microhardness is an indirect indicator of degree of conversion. It should be noted that microhardness depends not only on degree of conversion, but also on cross-link density in the polymer matrix, Chemical composition (quantity of inorganic fillers), matrix composition, and color and translucency of the material. Calgaro et al. reported a positive correlation between results from Fourier-transform infrared spectroscopy and microhardness, which, despite being two different protocols, are both appropriate to evaluate degree of conversion 10 .

Some studies have used the ratio between bottom and top surface microhardness to evaluate curing depth or effectiveness of light curing, considering that a ratio of 0.8 indicates good polymerization of compound resins, although its clinical relevance has not been proven 17 .

Since there are few studies analyzing shorter polymerization time with interposition of dental ceramic, we were interested in assessing how and how much the polymerization time affects the material by reducing exposure time to light. The aim of this study was to determine Vickers microhardness of top and bottom surfaces of compound resins photoactivated with interposition of machined feldspathic ceramic using 25 % and 100 % of the light-curing times specified by the manufacturers, and to calculate the ratio between Vickers microhardness values recorded at the bottom and top surfaces.

MATERIALS AND METHOD

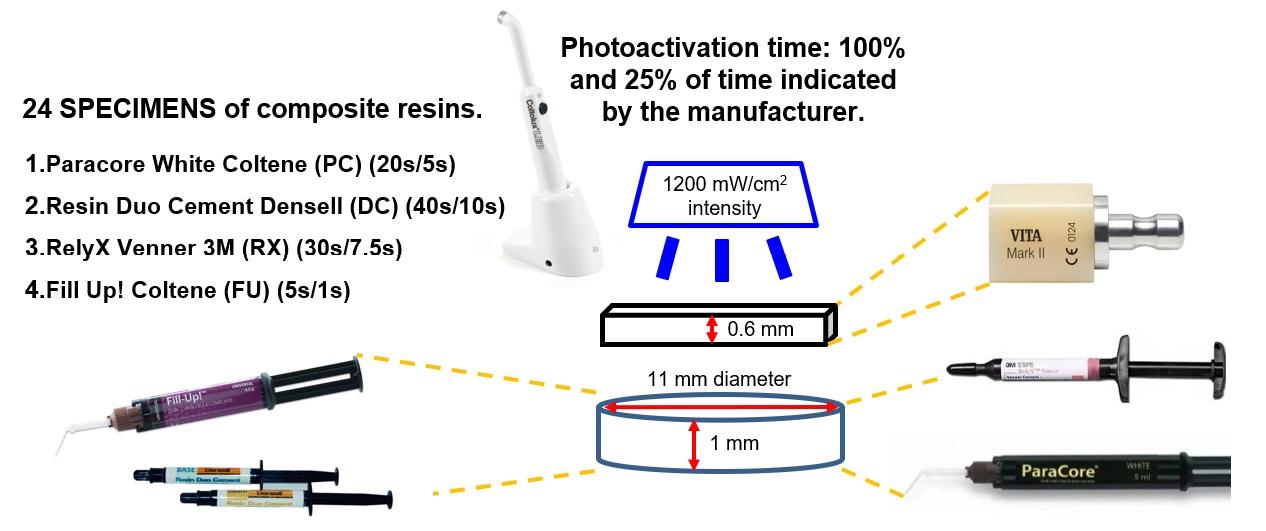

A total 24 specimens 11 mm in diameter and 1 mm thick were made from 4 resin-based cements: Coltene Paracore White (PC), Densell Resin Duo Cement (DC), 3M RelyX Veneer (RX) and Coltene Fill Up! (FU). During specimen photoactivation, a 0.6 mm layer of Vita Zahnfabrik Vitablock Mark II color 2M2C machined feldspathic ceramic was interposed between the light and the specimen. The resin-based cements were polymerized with a LED (Coltene) light with intensity 1200 mW/ cm2 for 100 % or 25 % of the times recommended by the manufacturers. The times applied to the different materials (corre sponding to 100 % and 25 %, respectively, of their total activation times) were the following: PC: 20s/5s, DC: 40s/10s, RX: 30s/7.5s and FU: 5s/1s. Each group contained three specimens. All specimens were stored dry in darkness at 37 °C for 7 days (Fig. 1).

Fig. 1 Materials used, activation times equivalent to 100 % and 25 % of the times indicated by the manufacturers, and specimen measurements.

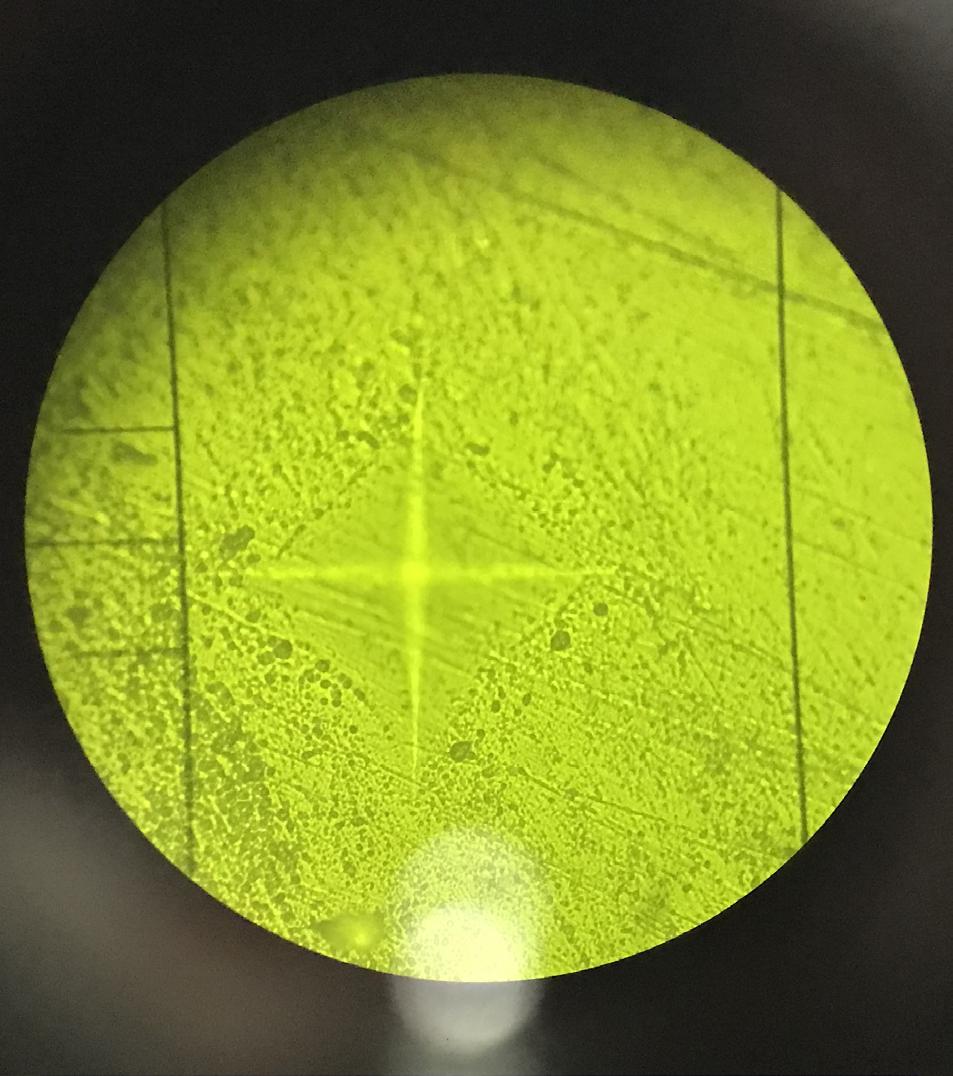

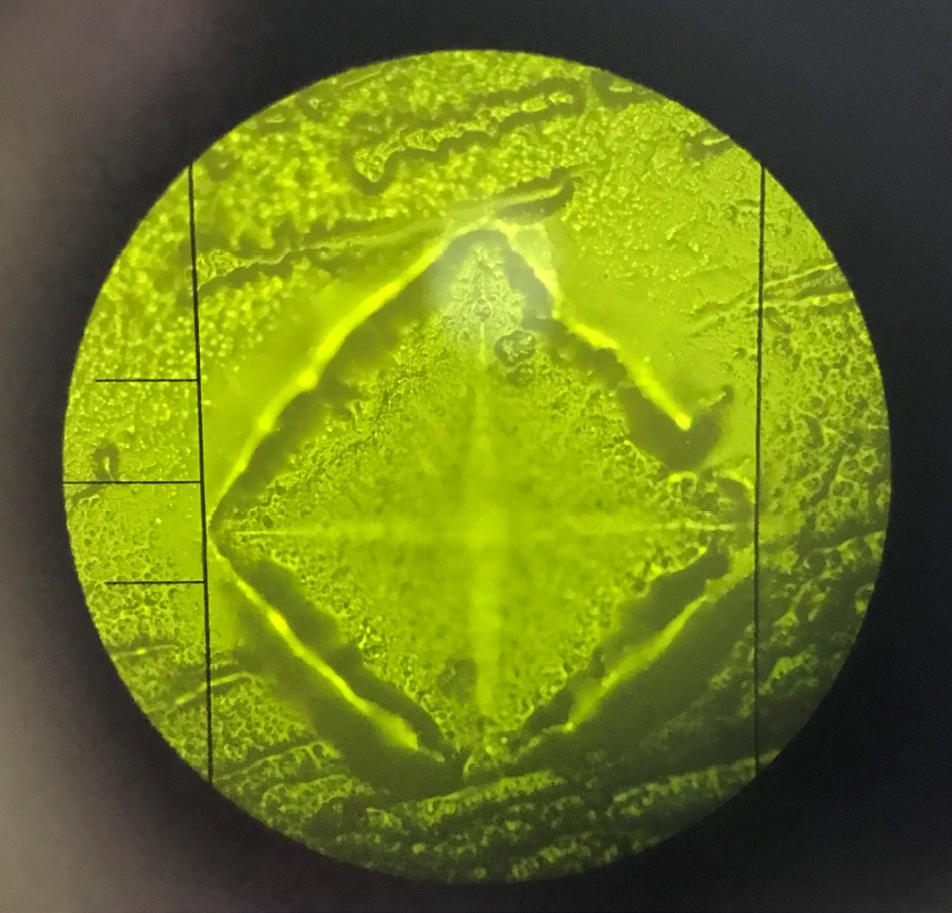

Three Vickers microhardness measurements were taken on the top surface (Fig. 2) and bottom surface (Fig. 3) of each specimen using a Vickers Future Tech FM300 microhardness tester (300 g, 5 s) and averaged. The average values for each surface were used to calculate the bottom/top ratio for each specimen. The results were analyzed using ANOVA for the factors ‘material’ and ‘polymerization time’, and using repeated measures for the factor ‘surface’. The bottom/top microhardness ratio was analyzed by two-way ANOVA complemented with multiple comparisons by Tukey’s test. The significance level for all tests was established as p<0.05.

Table 1 Materials used in the study.

| MATERIALS | TYPE | MANUFACTURER | BATCH NUMBER |

|---|---|---|---|

| RelyX Veneer (RX) | Light-cured Composite resin | 3M ESPE | N875393 |

| Paracore White (PC) | Dual-cured Composite resin | Coltene | I66285 |

| Resin Dúo Cement (DC) | Dual-cured Composite resin | Densell | RI0402-B (Base) RZ0402-C (Cat) |

| Fill Up! (FU) | Dual-cured Bulk fill Composite resin | Coltene | I91924 |

| Vitablock Mark II | Feldspathic CAD CAM glass ceramic | Vita Zahnfabrik | 45080 |

RESULTS

Mean (standard deviation) for each group using complete photoactivation times were: Top: PC 50.7 (6.3); DC 43.7 (2.5); RX 49.7 (3.9); FU 37.6 (7.9); Bottom: PC 26.1 (4.8); DC 24.0 (3.8); RX 28.6 (3.2); FU 21.9 (2.4). Using 25 % of photoactivation times they were: Top: PC 43.2 (1.6); DC 24.4 (3.7); RX 39.8 (3.1); FU 37.4 (2.2); Bottom: PC 20.7 (2.0); DC 19.4 (0.5); RX 20.4 (1.4); FU 23.6 (4.0) (Table 2). ANOVA showed a significant effect of all three factors - ‘material’, ‘polymerization time’ and ‘surface’ (p<0.01). Third order interaction was also significant (material, time, surface). This makes it recommendable to analyze each experimental situation separately. Differences were analyzed based on the confidence intervals (95 %) for the arithmetic mean of each experimental group.

Table 2 Descriptive statistics: microhardness

| Material | Time | Surface | Mean | Stand. dev. | Conf. Int. (95%) | |

|---|---|---|---|---|---|---|

| Lower Limit | Upper Limit | |||||

| RX | 25 | 1 | 39.8 | 3.1 | 34.9 | 44.7 |

| 2 | 20.4 | 1.4 | 17.1 | 23.8 | ||

| 100 | 1 | 49.7 | 3.9 | 44.8 | 54.6 | |

| 2 | 28.6 | 3.2 | 25.3 | 32.0 | ||

| FU | 25 | 1 | 37.4 | 2.2 | 32.5 | 42.3 |

| 2 | 23.6 | 4.0 | 20.3 | 26.9 | ||

| 100 | 1 | 37.6 | 7.9 | 32.7 | 42.5 | |

| 2 | 21.9 | 2.4 | 18.6 | 25.2 | ||

| DC | 25 | 1 | 24.4 | 3.7 | 19.5 | 29.3 |

| 2 | 19.4 | 0.5 | 16.1 | 22.7 | ||

| 100 | 1 | 43.7 | 2.5 | 38.8 | 48.6 | |

| 2 | 24.0 | 3.8 | 20.7 | 27.3 | ||

| PC | 25 | 1 | 43.2 | 1.6 | 38.3 | 48.1 |

| 2 | 20.7 | 2.0 | 17.4 | 24.0 | ||

| 100 | 1 | 50.7 | 6.3 | 45.8 | 55.5 | |

| 2 | 26.1 | 4.8 | 22.8 | 29.4 | ||

Means (standard deviation) of the ratios calculated and for each group with complete photoactivation times were: PC 0.53 (0.12); DC 0.55 (0.11); RX 0.58 (0.04); FU 0.61 (0.15). For 25 % of the photoactivation times, they were: PC 0.48 (0.03); DC 0.81 (0.16); RX 0.52 (0.02); FU 0.63 (0.07) (Table 3). Analysis of the bottom/top microhardness ratio showed a significant effect only for the factor ‘material’ (p=0.03). The bottom/top microhardness ratio was not affected by the difference in polymerization time for any of the groups. Global comparison of means using Tukey’s test showed a difference between PC and DC (Table 4).

Table 3 Descriptive statistics: bottom/top ratio

| Material | Time | Mean | Stan. dev. | Conf. Int. (95%) | |

|---|---|---|---|---|---|

| Lower Lim. | Upper Lim. | ||||

| RX | 25 | 0.52 | 0.02 | 0.39 | 0.64 |

| 100 | 0.58 | 0.04 | 0.45 | 0.70 | |

| FU | 25 | 0.63 | 0.07 | 0.51 | 0.76 |

| 100 | 0.61 | 0.15 | 0.48 | 0.73 | |

| DC | 25 | 0.81 | 0.16 | 0.69 | 0.94 |

| 100 | 0.55 | 0.11 | 0.43 | 0.68 | |

| PC | 25 | 0.48 | 0.03 | 0.36 | 0.60 |

| 100 | 0.53 | 0.12 | 0.40 | 0.65 | |

DISCUSSION

Resin-based luting agents are indicated for attaching ceramic veneers 3 . Light-cure and dual-cure materials need adequate light energy to polymerize properly 1,2 . Light transmission through ceramic veneers is critical to light-cure materials 7 , while it may be assumed that in dual-cure materials, the chemical curing compensates the reduction in light energy. However, Kilinc et al. and Calgaro et al. compared light-cure and dual-cure materials, demonstrating that the chemical curing reaction in a dual-cure resin was not sufficient to achieve máximum monomer conversion without the presence of light10,13,15.

The interposition of ceramic may cause attenuation and increased scattering of light, thereby reducing the amount of energy reaching the resin cement and leading to a lower degree of conversion. However, Pazin et al. concluded that the thickness of the ceramic layer had no significant effect on light-cure materials, though it did affect dual-cure materials, in contrast to several other studies that found that both kinds of material were affected by the thickness of the layer of interposed ceramic8,9,16,17.

Manufacturers say that light passes through 2 mm of composite resin. In the current study, total thickness was 1.6 mm, but included two different materials. According to the thickness, it should polymerize correctly, and the feldspathic ceramic with high glass matrix content is expected to allow light to pass without affecting the polymerization of the resin-based cement throughout its entire thickness. However, the current study found that microhardness values were significantly lower on the bottom surface. Fill Up! (FU), a low-viscosity dual-cure bulk-filled composite, was selected for use in the current study because the manufacturer states that it allows polymerization of layers up to 4-6 mm thick. However, this study found that FU microhardness was lower on the bottom surface than the top surface, just as it was in the other groups.

A study by Jang et al. found a lower conversion degree in dual-cure resin cements when using lower exposure times to light and with interposed ceramic 14 . The current study found no significant difference in bottom/top microhardness ratio between light-cured and dual-cured resin-based cements, despite the chemical activation present in dual-cure materials, thus confirming that the two activation systems do not work in synergy, in agreement with Jang et al. A study by Novais et al. concluded that there was no difference in conversion degree between light-cured and dual-cured resin-based cements when they were used to lute a translucent ceramic less than 1.0 mm thick 5 , once again confirming the lack of synergy between the two systems.

Light transmission through a material differs according to wavelength. Longer wavelengths with lower frequencies undergo less scattering within the material and therefore have better transmission. Violet light (wavelength 350-425 nm) has been found to penetrate better than blue light (wavelength 425490 nm). A slight difference in wavelength causes a difference in light scattering within a material. This is important for the quality of restorative dental procedures. Photoinitiators that are sensitive to shorter wavelengths are known to be more effective due to their ability to generate more free radicals with less energy, and are present in many restorative composites. For indirect restorations, a resin cement with a more efficient photoinitiator would provide a higher degree of conversion and therefore better physical, mechanical and aesthetic properties, as well as a reduction in clinical procedure time. However, the fact that the absorbance of violet is significantly higher than the absorbance of blue indicates potential to reduce photoactivation of resin cements containing photoinitiators activated by short wavelengths 4 . Camphorquinone is a type II photoinitiator system sensitive to the blue region of the visible light spectrum (425-510nm), while some type I photoinitiators (Lucirin TPO) are sensitive to the violent region (380-425nm). Type I photoinitiators are known to be more efficient at generating free radicals. However, violet light has little penetration into materials, so the use of a type I photoinitiator may be insufficient for adequate activation of the compound resin at the bottom 12 . Although manufacturers often do not specify photoinitiator type, it is a factor to consider during photopolymerization. The different microhardness values in the current study may be due to the photoinitiators present in the materials used. Microhardness may differ greatly among different materials, and this study was no exception. These results may be due to the difference in the components in the luting resins studied, such as monomers, initiators and inorganic fillers. In this context, larger amounts of triethylene glycol dimethacrylate (TEGDMA) in the organic matrix of the resin cements would provide a higher degree of conversion. The TEGDMA short aliphatic chain can move more easily within the resin structure and therefore react to a greater extent with the bisphenol-A ethoxylated dimethacrylate (Bis-EMA) and bisphenol-A-glycidyl methacrylate (Bis-GMA), both of which are more viscous monomers that include aromatic rings in their carbon chains that restrict their mobility 11 . All the cements tested in the current study contained TEGDMA and Bis-GMA. However, because the manufacturers do not specify the amount of each component in the resin cement, any interpretation of the results based on the composition of the organic matrix would be speculative.

Althoughthereisacorrelationbetweenmicrohardness and degree of conversion, photoactivation through the ceramic reduces the light intensity reaching the resin-based cement, and forms a polymer with few chain crosslinks. Moreover, microhardness may differ among different materials due to differences in composition, amount of chemical activator, photoinitiators and general composition of the resin-based cement such as type and proportion of monomers 10 . A high microhardness value in one material does not always mean that degree of conversion was higher. It is recommendable not to compare different materials, but only to compare microhardness of the same material. Pisheva et al. reported that light-cured materials had lower microhardness than dual- cured materials. Nevertheless, we agree that it is best to analyze each material individually 6 .

The analysis of hardness values in the current study found a significant difference in the factor ‘group’ due to the different chemical composition of each kind of material, and significant interaction because the difference in hardness values for each surface is related to both ‘polymerization time’ and ‘composition’. It is logical to have differences between surfaces and in absolute values for each material. It is advisable to analyze each experimental situation separately using confidence intervals. The results per material with complete curing time and top surface show absence of any interval overlap of between FU and PC. Analysis of top and bottom surfaces for 25% curing time per material shows that in DC there was no significant difference (overlapping intervals), but in this case, it is interesting to note that hardness achieved with 25 % was much lower than hardness achieved with 100 %. Bottom hardness with 100 % did not differ from top hardness with 25 %.

Analysis of the ratio showed no significant difference according to polymerization time, which cannot be evaluated with this sample size.

As reported in some reviews, the analysis of the effect of curing factors cannot be generalized for all composites because they are influenced by factors such as monomer type and polymerization reaction initiating system present in the composition, translucency, hardness provided by polymerization time, ceramic phase and possibly some other factor.

CONCLUSION

Under the experimental conditions in this study, it may be concluded that shorter photopolymerization time and interposition of restorative material significantly affect polymerization quality evaluated by hardness values, but the bottom/top ratio may not be affected by differences in polymerization time.

Analysis should be individual for each specific product, although some general recommendations can be made, such as maintaining photoactivation times, power of the device used, source/surface distance, among others.